Colorimetry quality control of Beer using a mini spectrometer

The quality control of a beer means ensuring it meets the specifications set in place for the style of beer, and keeping future batches consistent. Being able to track and objectively record values pertaining to every step of production ensures specifications are met and consistency is achieved. UV-VIS and NIR spectroscopy provide an accurate and convenient method to monitor quality through every stage of the production for the beverage industry, especially beer.

Spectroscopic quality control

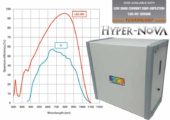

Spectroscopy works on the principle that light interacts with all forms of matter in a several different ways. Light can be absorbed, reflected or transmitted. Measuring light’s interaction with certain matter can provide valuable insight about a material’s composition and properties. Spectroscopic quality control testing provides a straightforward, low-cost method capable of rapid samples analysis. Spectroscopy is considered a nondestructive analysis method and allows data to be gathered without the need to sacrifice raw materials or products for one test. Multiple tests can be performed on one cuvette with little to no sample preparation. The ability to perform most measurements with minimal sample preparation aids in the ease of use and provides the ability to acquire results quickly. Using an affordable multipurpose instrument can provide benefits to a brewery or beverage manufacture.

Spectroscopy for each stage or production

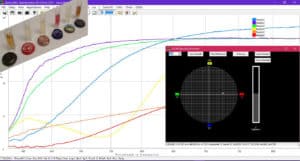

When it comes to the quality of control of beer, compact spectrometers show their value in the variety of their testing capabilities. Spectroscopic measurements can be implemented in every stage of brewing, from analyzing raw materials to measuring the color of a finished beer in the bottle. Near-infrared (NIR) absorbance measurement is one technique that can be utilized throughout the entire brewing process. NIR spectroscopy can measure percent of moisture, starch and protein in grains and other raw materials before brewing starts. Before fermentation can begin, the mixture of grains and water — called the wort — needs to be tested for the amount of amino acids present. The free amino nitrogen (FAN) levels in the wort are crucial to the propagation and growth of yeast in the wort.

The bitterness helps to offset the sweetness from the sugar in the grains, and can add a citrusy like flavor and aroma to certain beer styles. Some styles, like India pale ales, require a large amount of hops to get the correct flavor profile. Hop oils will absorb light in the UV region, and there is a linear relationship to the light absorbed and the concentration in the sample. Before a finished batch can be bottled and put in front of a customer, there is typically a testing and sensory panel that the beer must pass through. In these tests, specially trained personnel will taste and observe the beer for several qualities. A trained quality control tech will never be replaced by an instrument for mouth feel and off flavors. However, more subjective measurements, like color and clarity, can be made measurable using a miniature spectrometer. A probe and light source can be used with a UV-VIS spectrometer to take color measurements of finished beer and allow for quantifiable color matching, providing reliable data.

Defect mitigation

Brewing is not like most manufacturing operations when it comes to dealing with defects. With most manufacturers, a single defective product in a batch can be fixed or eliminated and the cost is minimal. In  brewing it takes roughly the same amount of time to brew five gallons of beer as it does to brew 500 gallons. The only difference is the size of the tanks and the quantity of ingredients. Because of this, breweries favor producing in large quantities, such as several hundred gallons per batch. If uncorrected, this issue can cost a brewery several thousand dollars. In smaller breweries it is cost-effective to send samples out to labs for analysis. However, this takes time, and if a problem is detected too late, it could mean a loss of beer and profits for the brewery.

brewing it takes roughly the same amount of time to brew five gallons of beer as it does to brew 500 gallons. The only difference is the size of the tanks and the quantity of ingredients. Because of this, breweries favor producing in large quantities, such as several hundred gallons per batch. If uncorrected, this issue can cost a brewery several thousand dollars. In smaller breweries it is cost-effective to send samples out to labs for analysis. However, this takes time, and if a problem is detected too late, it could mean a loss of beer and profits for the brewery.

Mitigating product loss is an important part of any quality control department. Allowing a product that doesn’t meet specifications to be released can have worse results down the line. In an industry that prides itself on consistently delivering a quality product, lacking in either consistency or quality can literally and figuratively leave a bad taste in customers’ mouths. Unfortunately for breweries, an unhappy customer is far more likely to tell a friend about a bad experience than a good one.

Universal applications

Spectroscopy is a method for quality control that has applications across many industries. Spectrometers can be adapted for limited measurements including: chemistry, colorimetry, light measurement, thin film measurements and many more. The ability of a low cost spectrometer to perform multiple types of measurements makes them a valuable addition to any facility concerned with quality of their products.